This isn't too easy a job, but it's doable and with the part alone costing £119 from BMW, the savings on labour are worthwhile. Getting to the propshaft is the most involved part of the task as it's right up above the exhaust, which needs be taken off too, so if you're working at home make sure you've got ramps with

, axle-stands just won't cut it - there's a lot of work under there.

The old one, left, doesn't look too bad, but the metal rings have all separated from the rubber and have a lot of play in them.

PROCESS:

Lift the front of the car on ramps.

Removing the Exhaust:

1. Unscrew the four bolts on the two joint-brackets, located just behind the steel-braided flexible sections beneath the driver's seat, using a 13mm wrench. [Mine seized after a few turns, but I was able to get a hacksaw blade into the gap and had to cut them off and find new ones.]

2. Gently slide the flexible section of each front-pipe back about an inch until they are clear of the exhaust.

3. On the exhaust centre-bracket, remove the 2 nuts from the inner-centre of the plate using a 13mm wrench.

4. Remove the 4 bolts from the corners of the centre-bracket plate using a 13mm wrench and gently work it down until it is free of the studs on the exhaust-hangers.

5. Remove the 2 nuts from the front exhaust-bracket [with the round rubber-bushes] using a 10mm wrench, then tilt the exhaust until both the upward and downward facing studs are free of their brackets and gently lower the exhaust so it is resting on the rear hangers.

6. Lift the rear-silencer up into its recess and remove the two rubber exhaust-hangers from their hooks. [The benefit to removing these last is that the exhaust can be manipulated best to loosen the rubber-hangers, as they are mighty tough to get off.]

7. Lower the complete exhaust to the ground and gently slide it out from the rear of the car.

Removing the Heat-Shielding:

8. Remove the 2 screws holding the o/s of the large centre heat-shield and 1 nut on the n/s, using a 10mm wrench. The heat-shield should drop down easily.

9. There is a smaller heat-shield [in the pic below] to the o/s front of the transmission-tunnel that also needs removing, as it partially covers the bolts for the gearbox-suspension. There is a small 10mm nut at the rear-edge and another hidden where the shield curves down at the front. The third, larger nut at the front is connected through a solid bracket, which is a lot of work to remove and unnecessary - it's best to just bend the heat-shield out of the way or force it from underneath the bracket and make a gap in the ring so it slides back under easily.

Lowering the Propshaft and Removing the Donut:

TIS or the Workshop Manual say to remove the complete propshaft to get at the donut, but this is not necessary - the propshaft can be lowered with the diff end still attached enough to get the donut off without causing any damage so don't worry, there's no need to remove the rear UV-joint or mark any positions.

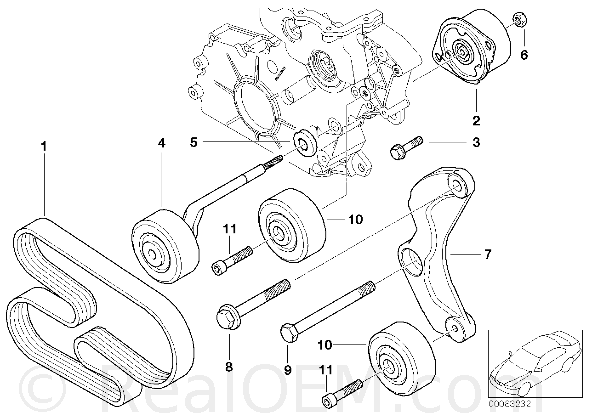

10. Remove the cross-member bracket, just to the rear of the gearbox-suspension, by unscrewing the 4 bolts with a 13mm wrench.

11. Unscrew the two large counterweight nuts from the gearbox-suspension using a 13mm wrench. The heavy cylindrical one is n/s, the shaped one o/s.

12. Support the gearbox on a jack and lift it slightly so weight is off the dampers.

13. Remove the 4 bolts from the gearbox-suspension mount using a 13mm wrench and work it free of the two studs on the rubber-dampers.

14. Remove the bracket holding the dampers by undoing the 2 nuts on the upper side of the bracket using a 13mm wrench. The nuts only need undoing a few turns and the bracket should slide off its mounts on the gearbox.

15. Remove the 6 nuts and bolts from the front end of the propshaft that connect it to the gearbox, using an 18mm wrench and spanner. [There is a chuck on the end of the propshaft that extends through the donut so there's no need to leave one bolt in to hold it up.]

16. Support the weight of the propshaft and remove the two nuts holding the centre-bearing bracket in place using a 13mm wrench and gently lower the centre of the propshaft, sliding the front end clear of the gearbox as you do so. Once the front end is free, lower the front of the propshaft to the ground so only the rear UV-joint is attached, or suspend the prop from some metal-wire if you're using full-height ramps.

17. Work the rubber-donut off from it's 3 mounting collars on the propshaft using a flathead screwdriver.

Fitting the new Donut:

18. It doesn't matter which way the donut faces, but 3 of the 6 bolt-holes on either side have extended metal collars, which fit into corresponding recesses on the propshaft and gearbox bosses, so these need lining up correctly when replacing the bolts.

19. The tightening torque for the 6 bolts is coming here, but we couldn't get an angle on our torque-wrench in the gap under the car, so we just gave them a good graunch and haven't had any vibrations.

20. Reverse steps 16 to 1.